I’ve worked on a broad range of technical projects over the past 5 years, all of which have been a tremendous learning experience and a lot of fun. I’ve highlighted a few of the more unusual or interesting ones below.

Mars Society UK R&D

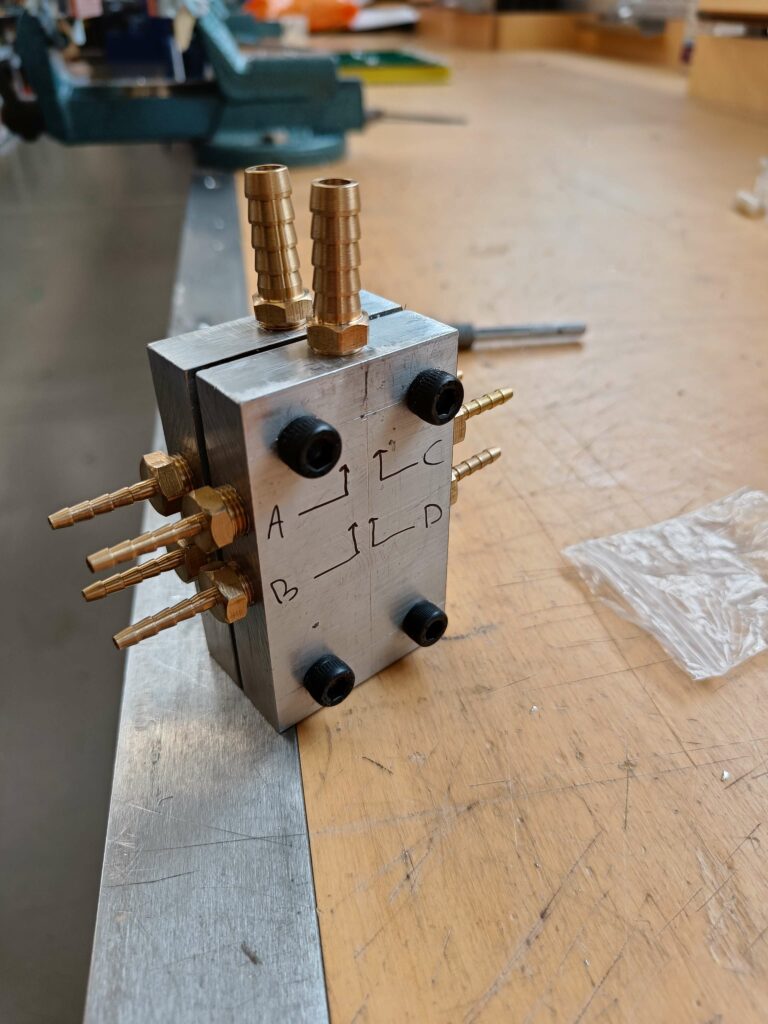

In 2023 I was appointed R&D Technical Lead (or Chief Engineer) of the UK Mars Society, leading all the technical development work for the group. My work thus far has involved hardware development for the as-yet-unnamed project on spacesuit portable life support systems.

Progress thus far has focused on design of a highly testable Liquid Cooling Garment, with the attendant control and data system, and a force feedback system to simulate pressurised spacesuits.

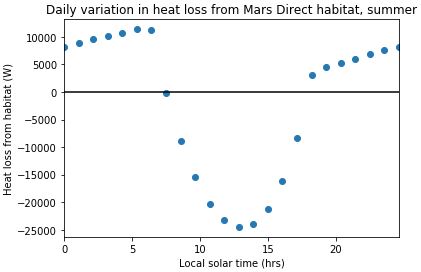

Syrtis thermal modelling

In 2022 I wrote the Syrtis code, a Python module that calculates thermal balance for Martian habitats. I presented Syrtis and some of the fun quirks of the Martian thermal environment at the International Astronautical Conference 2022 in Paris, and virtually at the Mars Society’s 2022 Convention. While Syrtis development has now concluded, I’ve continued to use it as a tool to analyse space habitats on Mars and beyond. If you want to discuss Syrtis or thermal modelling for your project, shoot me an email.

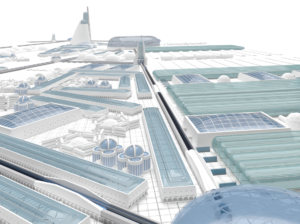

Nexus Aurora Martian City-State

In the first half of 2020 I worked with the Nexus Aurora citizen science community on an entry to the Mars Society’s City-State Design Competition. We ultimately designed a sprawling metropolis of basalt fibre and steel in Hellas Planitia, full of little gems like a methane-electric high speed freight rail and a modular robotics system to do everything from transport cargo to manufacture pharmaceuticals.

I led the Logistics & Infrastructure domain in the design phase, which formed the foundation of many other fascinating designs in the city. I specified standard containers for robotic transport, worked with colleagues to design railway systems, contributed to the design of manufacturing facilities and generally had an absolute blast.

Once our designs were broadly collated I was the lead author of our 20 page final report (which was the product of a madcap 1-week sprint involving over 30 editors, visual artists, factcheckers and technical advisors). The report was successful enough to get us to the top 10 from over 170 teams, so I then took on the task of designing the 30 minute presentation at the Mars Convention. I opened this presentation at the Convention, and we ultimately were awarded first prize by a panel including Robert Zubrin.

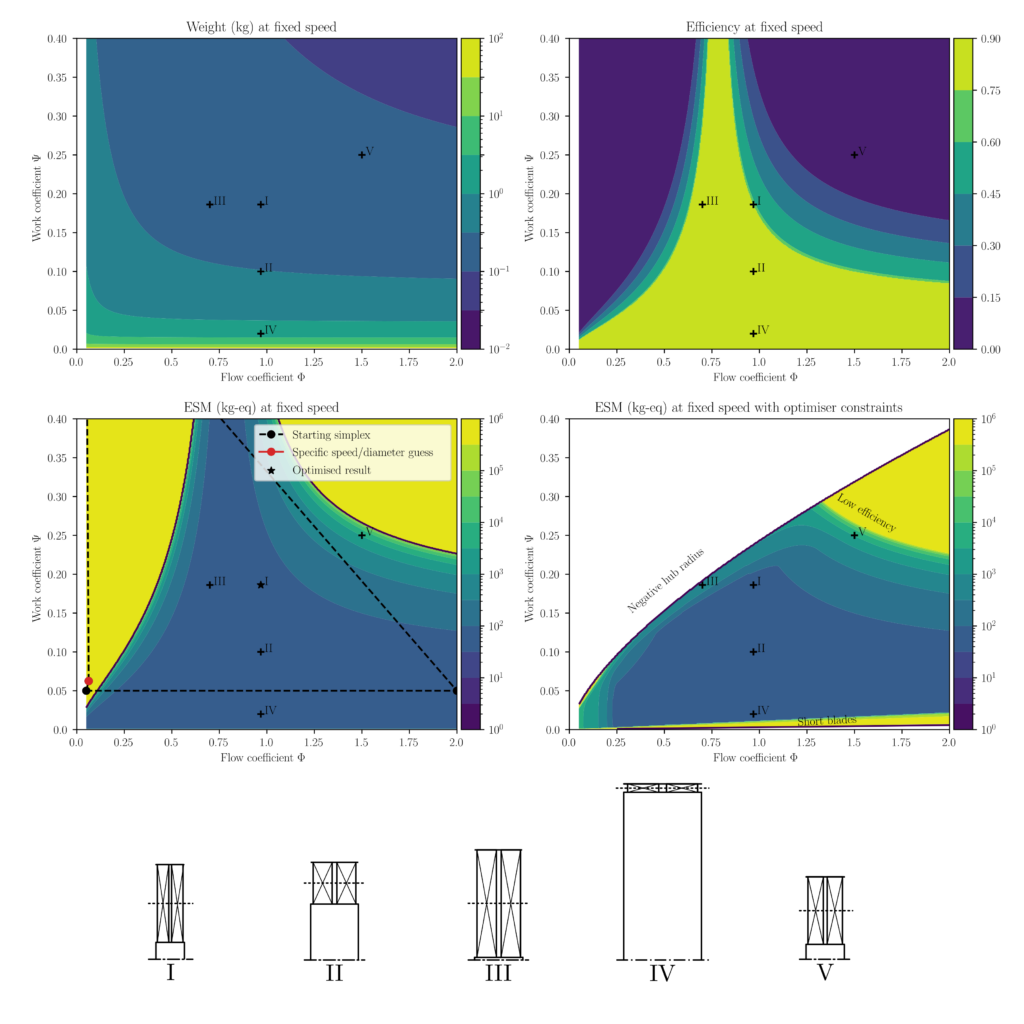

ISRU Master’s Thesis

In the academic year 2022-23 I completed a Master’s thesis titled “Optimisation and design of a compressor for atmospheric resource extraction on Mars” under the supervision of Dr Nick Atkins in the Whittle Laboratory, Cambridge.

Over the course of the year, I set up a design scheme for intercooled compressors in the Martian environment and ran optimisation to determine the best system to supply carbon dioxide to the propellant production system of Starship. I was able to demonstrate that an intercooled, turbomachinery-heavy approach can deliver an improvement over state-of-the-art of a factor of five or more.

While I have concluded the direct turbomachinery work with the end of the thesis project (for which I was awarded a First!) I am continuing to chip away on interesting thermodynamics and thermal challenges in the Martian industrial system.

CHASM conference

In 2022 I joined the committee of the Community of Human Analog Space Missions, working to connect the analog space field around the world through conferences and workshops. At CHASM I’ve helped organise events across Europe, chaired workshops with amazing people and visited secret-ish underground research facilities.

In 2023 I became CHASM webmaster and lead for the CHASM wiki project, which aims to collate the wealth of data on analogs into a single home.

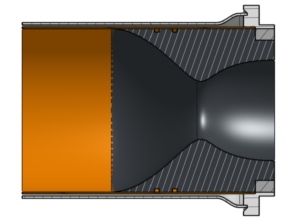

White Giant rocket engine

I’ve been working on systems engineering for the CUSF spaceshot rocket Griffin since March 2020, and formally kicked off the White Giant engine development in January 2021. White Giant is the latest and largest in CUSF’s Stellar engine series – a 10kN regeneratively cooled engine burning nitrous oxide and isopropyl alcohol. White Giant will burn for 30 seconds, lofting the Griffin vehicle to 20km at around Mach 3 before firing the Aquila solid-fuelled second stage to space.

The path to space has begun with the development of a battery of analytical tools (Midas, Octopus, Bamboo). In the next few months we will carry out cold-flow testing and two-phase injector characterisation, followed by the build and test firing of the White Dwarf 1kN engine.

In parallel to the White Giant development process I’m directing the development of the Aquila rocket/upper stage, and carrying out further high-level design of the Panthera first stage. This will be a mammoth rocket, weighing in at around 200kg and 6m tall. Unlike existing student sounding rockets (notably USCRPL’s Traveller IV) we are unable to use custom solid motors thanks to UK law. This ultimately results in the need for a very powerful long-burning liquid engine and sold upper stage.

Martian Agri-robotics

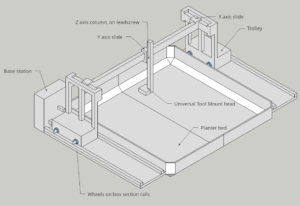

Along with a small team at Nexus Aurora, I conceptually developed an autonomous farming system specifically for use in large Martian agricultural volumes. I entered this design in a Call for Experiments from the Transatlantic Mars crew, a joint American/French team who’ll be doing a rotation at the Mars Desert Research Station in December 2021. The proposal was accepted so I set about designing a subscale (~1m2) farming system to be deployed in the MDRS GreenHab.

This design is well underway, drawing on a number of open source designs (primarily FarmBot and GoodEnoughCNC) with specialised mechanical and software aspects added where required. The agri-bot team is thoroughly international (mechanical design, software and manufacturing spans 3 continents) and will be one of the first major hardware projects for Nexus Aurora – along with the sister MDRS project, autonomous scouting robots.

Orbital CAN Engineering

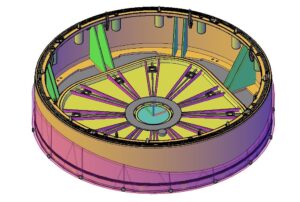

Another major project at Nexus Aurora is the family of projects around the Orbital CAN space station architecture. I’ve assisted in a few different technical aspects of this.

The Universal Berthing Mechanism (pictured above) is an evolved space station module berthing mechanism, specified to handle the next 50 years of LEO commercial and scientific development. I’ve assisted the team in specifying the MEP links between modules (power, coolant, data, experimental resources) and the complex plumbing required for maximum compatibility and simplicity of operations.

Across the aisle I’ve helped with high-level power and coolant system specification for the CAN module, used the UBM specification to limit station topologies and generally pushed the concept of operations for the architecture.

Sixth Form Turbojet

In retrospect, trying to build a metre-long turbojet engine in sixth form in a thoroughly poorly-equipped workshop may have been a bad idea. In the intervening years I’ve learnt a lot more theory that would have made for a much more successful project with more than a chance of spinning up successfully. But being forced to learn spectacularly complex theory from absolute scratch, and designing for hyper-constrained manufacture, was an absolutely tremendous experience and a load of fun for the whole team.